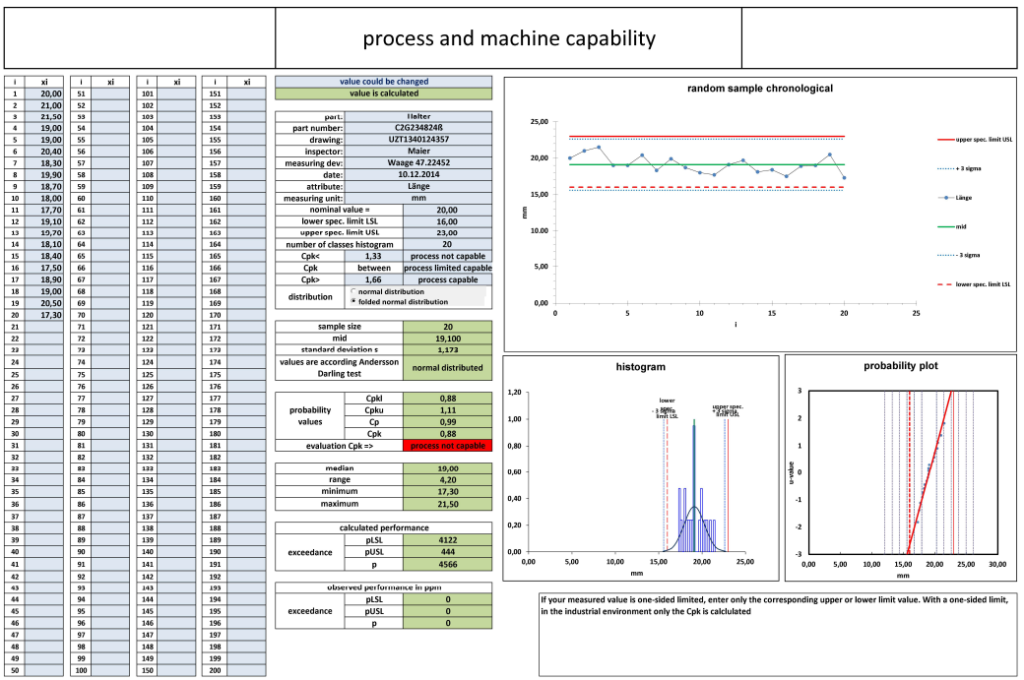

Process capability is a measurable property of a process against the specification, expressed as a process capability index (e.g., Cpk or Cpm). The output of this measurement is usually illustrated by a chronological control sample, a histogram and calculations that predict how many parts will be produced out of specification (OOS).

700+ companies trust us to achieve results for them with our Excel solutions.

How to calculate cpk in excel

Three possibilitis:

- Excel template with Macro

- Excel add in with office 365

- online calculation

1. Excel template with Macros

One way is to use the excel template with macros. You will get an excel template with:

- multilingual (german, englisch, italian, other languages possible)

- histogram, probabiltiy plot, chronological plot

- Excel template with macros .xlsm

- possibiltiy to format the cells, integrate the logo of your company, etc…………….

To receive the Excel template below, please send me your email address.

If you want to get the template without restrictions please check this possibility.

2. Excel Add in with office 365

The base of the calculation is a spreadsheet without macros.

You can make all adjustments like:

- inserting your logo

- formatting cells

- etc., etc.

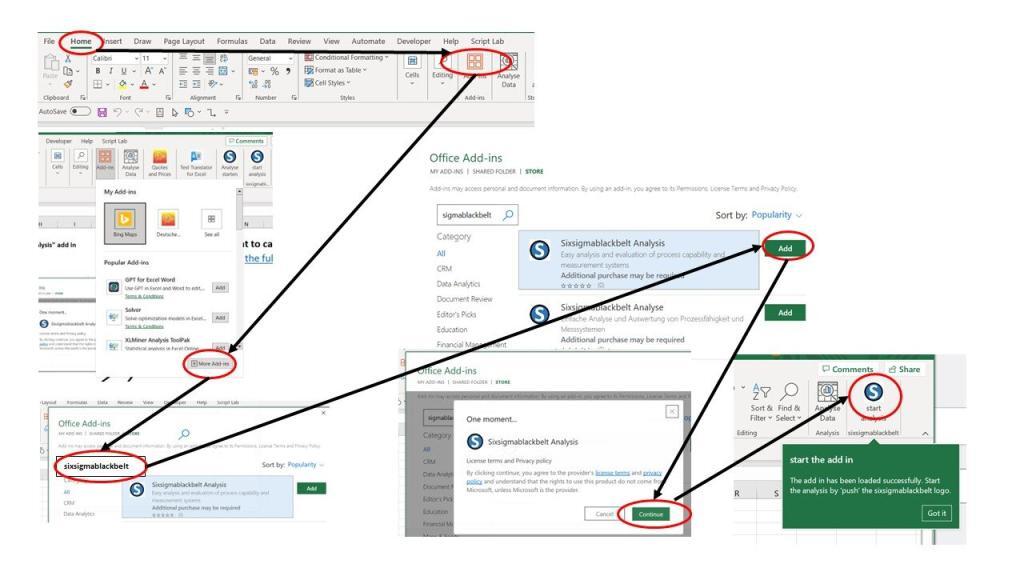

To calculate adjusted values, you need the Microsoft certified „Sixsigmablackbelt Analysis“ Excel „add in“.

The easiest way to get the „add in“ is to install the „add in“ via Excel.

If you do not have a template yet, press the button „Create template“. If you have opened the template above, simply change the values and press the „Calculate“ button.

28 seconds to get a process capability calculation

If you already have a template customized to your needs:

- just open it

- put the values in

- calculate the sheet

- and save the results

_

3. Cpk online calculator

For a first overview you can calculate the Cmk online on this site. Just edit the values or delete the values and copy your own values from Excel via CTRL+V.

If you find it helpful, please share.

–

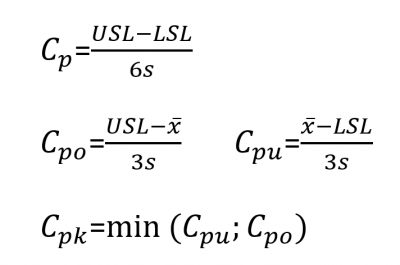

Formula to calculate

The base for the cpk formula is described here.

For a more scientific look at process control, check out this discussion on the Minitab blog. Another option is to look at the ASQ homepage.

Please feel free to contact me, if you have any suggestions for improving this page (roland.schnurr@sixsigmablackbelt.de).

Sources:

[1] (MSA) Measurement System Analysis | AIAG“. https://www.aiag.org/quality/automotive-core-tools/msa (17. April 2022).

[2] „IATF 16949-2016 | AIAG“. https://www.aiag.org/quality/iatf-16949-2016 (17. April 2022).